Truck Wash Racks – Automatic & Hand Wash Solutions

At Hydro Engineering, Inc., we provide comprehensive solutions for truck washing operations. Whether you're looking for an automated drive-through system or a manual hand-wash setup, we design, build, and support fully integrated systems tailored to your needs.

Complete Truck Wash Systems

Our custom truck wash racks can include:

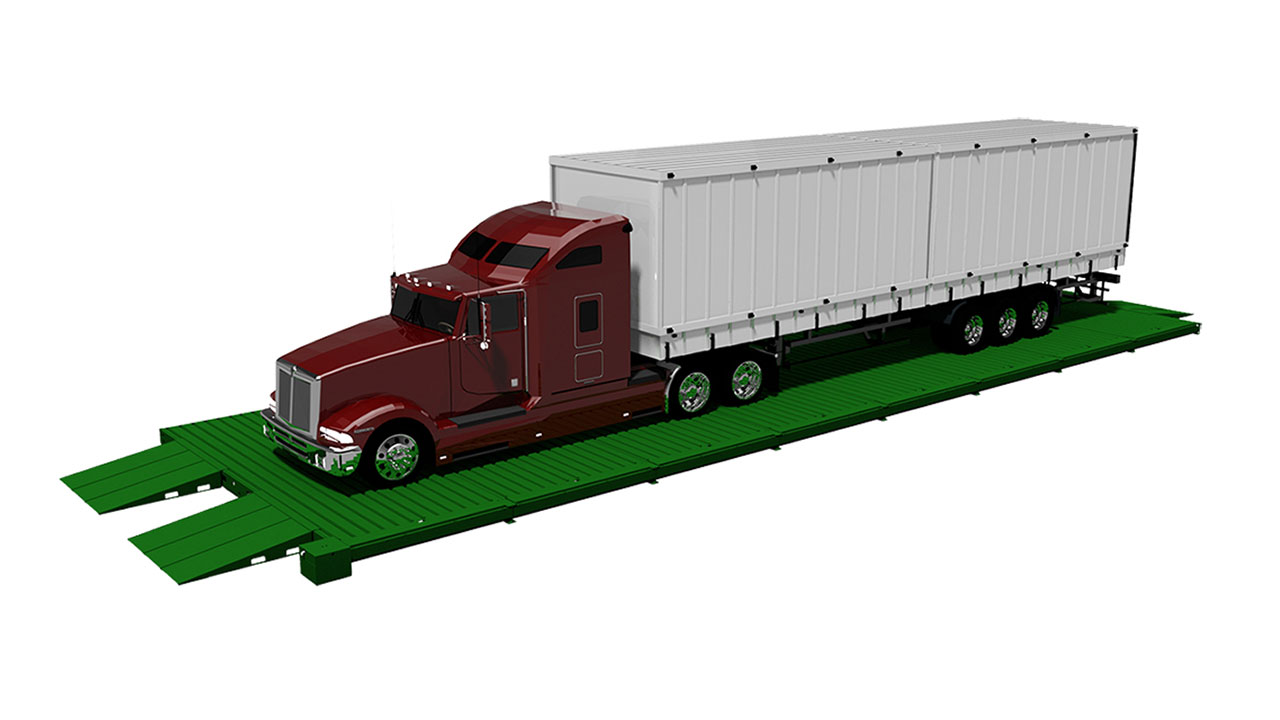

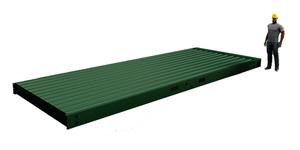

- Hydropad above-ground steel containment pads

- Hydroblaster high-performance pressure washers

- Hydrokleen wash water filtration and recycling systems

Looking to automate your wash process? Add:

- Drive-through undercarriage wash

- Side and top wash systems

These upgrades transform your wash rack into a fully automated truck wash that increases efficiency and reduces labor.

A Real-World Example: Big Savings Through Smart Recycling

The Wash Rack, a commercial truck wash facility in Salt Lake City, was spending approximately $1,375 per month on water.

After installing Hydro Engineering Inc.'s Hydrokleen filtration and recycling system, their monthly water bill dropped to $635.

Monthly Savings: $740

Annual Savings: $8,880

But the savings didn’t stop there.

A few months later, thanks to lower contamination levels in discharged water, the local sewer authority re-rated the facility’s account—dropping the sewer cost from $3.26 to $0.75 per 1,000 gallons.

Additional Monthly Savings: $791

Additional Annual Savings: $4,746

Total Annual Savings: $13,626

Ready to Cut Costs and Increase Efficiency?

Hydro Engineering, Inc. offers scalable truck wash solutions that help you clean better, save money, and operate responsibly. From containment to recycling, automation to support—we’re here to help every step of the way.

The Wash Rack Water Analysis

The Wash Rack Water Analysis