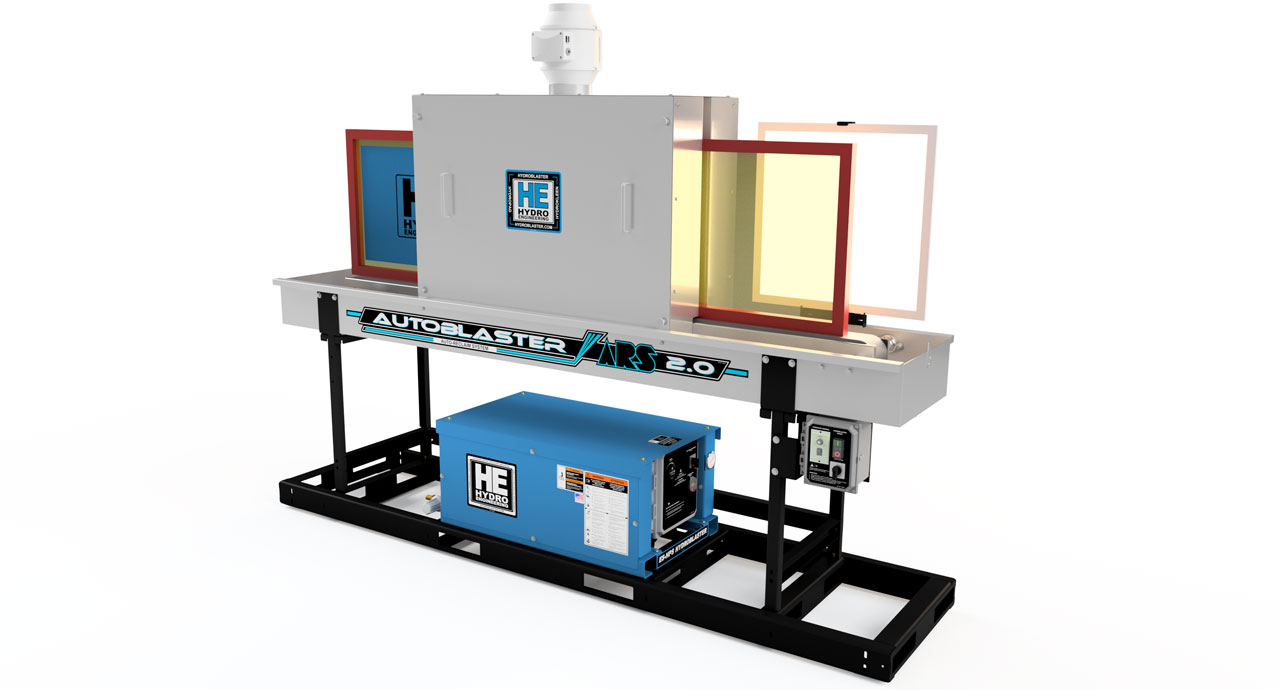

Autoblaster/ARS: Advanced Automatic Screen Reclaiming System for Screen Printers

Revolutionize Your Screen Reclaim Process

The Autoblaster/ARS is a cutting-edge automated screen reclaiming machine engineered for maximum safety, efficiency, and consistency. Designed to eliminate the risks and challenges associated with traditional hand-held pressure washing, the Autoblaster/ARS helps screen printing operations reclaim screens faster and more effectively—saving time, reducing labor, and improving results.

Why Choose the Autoblaster/ARS?

- Enhances Worker Safety: Eliminates the need for hand-held pressure washers, protecting operators from harmful chemical exposure and overspray.

- Boosts Productivity: Consistent reclaiming quality means fewer reworks and less operator fatigue.

- Cost-Effective Automation: Reduces chemical use and labor costs while maintaining high reclaim quality.

- Reliable Results: Delivers uniform screen cleaning every time, ensuring optimal performance for your next print run.

Engineered for Precision and Performance

The Autoblaster/ARS is optimized for 25" x 36" screen frames, a common size in the textile screen printing industry. With a conveyor-driven system operating at a steady 1 inch per second, screens are automatically guided through a powerful dual-sided high-pressure water jet system. This thorough and consistent cleaning mechanism significantly reduces the need for manual scrubbing or repeated washing.

- Hydraulic Power System: Adjustable pressure settings to fine-tune cleaning performance.

- Illuminated Inspection Station: Easily inspect screens immediately after cleaning for quality assurance.

- Durable Construction: Includes a stainless steel sump and automatic pump-out system for water and waste management.

Cleaner Screens with Fewer Chemicals

While emulsion remover and dehazer are still part of the process, the superior cleaning capability of the Autoblaster/ARS minimizes their usage—reducing operational costs and environmental impact.

Optimized Screen Reclaim Workflow

Step-by-Step Process Using the Autoblaster/ARS:

- Card off excess ink at the press and remove frame tape.

- Apply emulsion remover and allow a 30-second dwell time.

- Place the screen on the Autoblaster/ARS conveyor belt.

- Inspect screen after cleaning. If ghost images persist:

- Apply liquid haze remover, brush onto the ink well side, and allow to dwell.

- Re-run the screen through the Autoblaster/ARS.

- Wastewater and solids are collected and automatically pumped to your designated discharge point.

Smart Wastewater Management Options

To support varying production volumes, we offer two reclaim water filtration solutions:

- Low to Medium Volume (up to 20 screens/day): CFS3 Manual Solids Filter System

- High Volume (hundreds of screens/day): CMAFU-2 Automatic Solids Filtration System

Experience the Future of Screen Reclaiming

Stop dreading screen reclaiming—upgrade to the Autoblaster/ARS and transform your workflow with automation, reliability, and efficiency.

Contact us today to learn more or schedule a demo of the Autoblaster/ARS.

Model Specifications

Autoblaster/ARS

Autoblaster/ARS

Shop Drawings

Model Autoblaster / ARS

Model Autoblaster / ARS

Autoblaster/ARS Return On Investment Calculator

| Your Current Reclaim Method | |

|---|---|

| Screens per Day | |

| Current Time per Screen (min) | |

| Labor Cost per Hour | $ |

| Days Worked per Month | |

| Total Minutes per Day | |

| Total Hours per Day | |