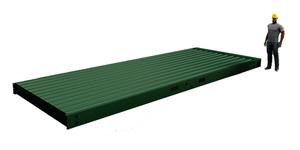

Aircraft Wash Rack Systems

Advanced Corrosion Control and Cleaning Efficiency

In military aviation, aircraft often spend more hours undergoing corrosion maintenance than in actual flight. Timely and thorough removal of corrosion-causing contaminants is among the most effective preventative measures in aircraft maintenance.

Hydro Engineering, Inc. delivers powerful, proven aircraft wash and rinse systems designed to meet the highest performance standards. Our solutions are ideal for hangars, airfields, or deployment operations, offering unmatched reliability and efficiency.

Why Aircraft Cleaning Matters

- Prevent corrosion by eliminating salt, electrolytes, and other contaminants

- Maintain clear visibility through canopies and windows

- Enable thorough inspection for corrosion and structural damage

- Improve turbine engine efficiency by reducing buildup

- Reduce fire hazards by removing residual fluids and debris

- Preserve aerodynamic performance and aircraft handling

- Maintain special paint scheme integrity

- Enhance the overall appearance of the aircraft

Even with modern coatings, treatments, and materials, regular wash and rinse decontamination remains a critical—and often the most effective—defense against corrosion.

Proven Performance & Savings

Hydro Engineering, Inc. systems not only improve cleaning outcomes, but also significantly reduce operational costs:

- Up to 60% reduction in man-hours required

- More than 90% savings in water consumption

- Approximately 75% less cleaning compound usage

These efficiencies result in faster aircraft turnaround, superior cleaning quality, and measurable cost savings.

Certified Quality You Can Trust

Hydro Engineering, Inc. is proud to be ISO 9001:2015 Certified. All our equipment is ETL Certified and manufactured to meet rigorous UL, CE, and CSA standards. Every unit is proudly Made in the USA.

Let’s Talk Aircraft Maintenance

Contact our team to learn how Hydro Engineering, Inc. can support your corrosion control and aircraft wash needs.