Hydropad Above Ground Steel Wash Pads

Creating a wash rack involves prioritizing the collection of wash water and contaminants. Hydropads are arranged to form a movable wash pad tailored to specific pressure washing equipment and water recovery needs. These modular systems support vehicle weights up to 75 tons per axle, are easily installed above ground with minimal site preparation, and can be relocated as needs evolve.

Constructing a wash rack includes incorporating approach/depart ramps, containment walls for overspray, awnings, remote equipment control stations, options for water collection and filtration, drive-over ramps for accessing vehicle undercarriages, and perimeter catwalks.

Hydropads serve as the fundamental elements for building equipment wash racks. By utilizing them, one can achieve pressure washing objectives, adhere to EPA regulations, cultivate an environmentally responsible corporate image, and successfully complete tasks at hand.

Hydropads Containment Pads are renowned as the top choice for above-ground wash pads

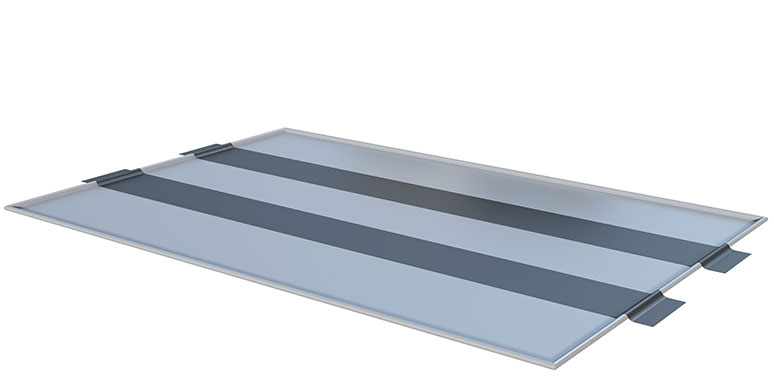

Hydropads stand out as the premier above-ground wash pads on the market. These modular units are remarkably easy to configure and assemble, seamlessly connecting to form arrays tailored to specific application needs. As requirements expand, so can the arrays.

Featuring robust all-steel construction and a corrugated surface for enhanced strength and integrity, Hydropads outperform competitors with flat or diamond plate surfaces prone to deformation under typical wash rack loads, resulting in water, oil, and debris retention.

The corrugated surface of Hydropads efficiently directs water and debris into channels that lead to side collection gutters, where high water flow automatically flushes away debris. This eliminates the need to chase water and debris around items on the wash rack surface, ensuring a clean and dry work area for operators.

Unique patented side gutters direct water and debris to the edges of the Hydropad, rather than collecting at a central point like competing wash racks. This design eliminates the hassle of moving heavy load-bearing grates or covers for maintenance while the wash rack is in use.

Optional variable-speed drag conveyor systems within the side gutters efficiently discharge solids above grade and automatically filter and pump out fluids. Unlike competitor pads, which may require multiple gutters and conveyors, Hydropads simplify complexity and maintenance.

Hydropads also offer customizable features such as flip screen inserts for turf equipment cleaning and skid steer drive-in clean out trays for primary solid settling and collection.

With unmatched capacities ranging from 2 to 75 tons per axle and patented self-standing wall designs reaching heights of up to 14', Hydropads provide unmatched structural strength and durability.

Protected by a rigorous powder paint process for superior corrosion resistance, Hydropads are built to withstand harsh conditions, passing stringent salt spray tests.

These pads seamlessly integrate with the AUWS Automatic Undercarriage Wash System for comprehensive wash spray containment and track-out prevention. Customization options include undercarriage, side, or top spray bars, inspection wash ramps, awnings, catwalks, and various hose handling and control station configurations.

As the pioneers and leaders in above-ground wash rack technology, Hydropads remain unrivaled in structural integrity and feature richness, backed by multiple patents.

Check out the Brochure!

Hydropad Systems

Hydropad Systems