Eliminate odors and wastes from wash water treatment systems with Hydro Biodigesters

Hydro Biodigesters

What are Biodigesters?

Biodigesters are a combination of naturally occurring bacteria, enzymes, micro and macronutrients, available in liquid or dry formula. They are used for odor control and organic reduction in wash water treatment systems. Biodigesters consist of naturally occurring bacteria that are listed on both the Generally Regarded as Safe listings of the US Food and Drug Administrations and the Association of American Feed Control Officials.

How do Biodigesters work?

When placed in the waste stream the Biodigester enzymes digest organic materials including oil, grease, fuels, fats, solvents, and other organic materials (all of which increase BOD and COD levels) first into starches and fats and then into sugars that are consumed by the Biodigester bacteria. Biodigesters offer the same digestion process used by sewage treatment facilities but at an accelerated rate.

Why use Biodigesters?

Biodigesters are cost effective, they are self-replicating, they do an excellent job of controlling odors and reducing a wide variety of organic wastes and they are safe. The byproducts of the Biodigester digestion process are harmless and odorless.

Alternate wash water treatment systems use oxidizers like chlorine, hydrogen peroxide, bromine and ozone which do a good job controlling odors and naturally occurring bacteria but aren't effective with solvents, oil and pesticides. Oxidizers are corrosive, dose rates are difficult to control because higher organic loads require higher dose rates to be effective and they are quickly depleted by chemical reaction and off gassing.

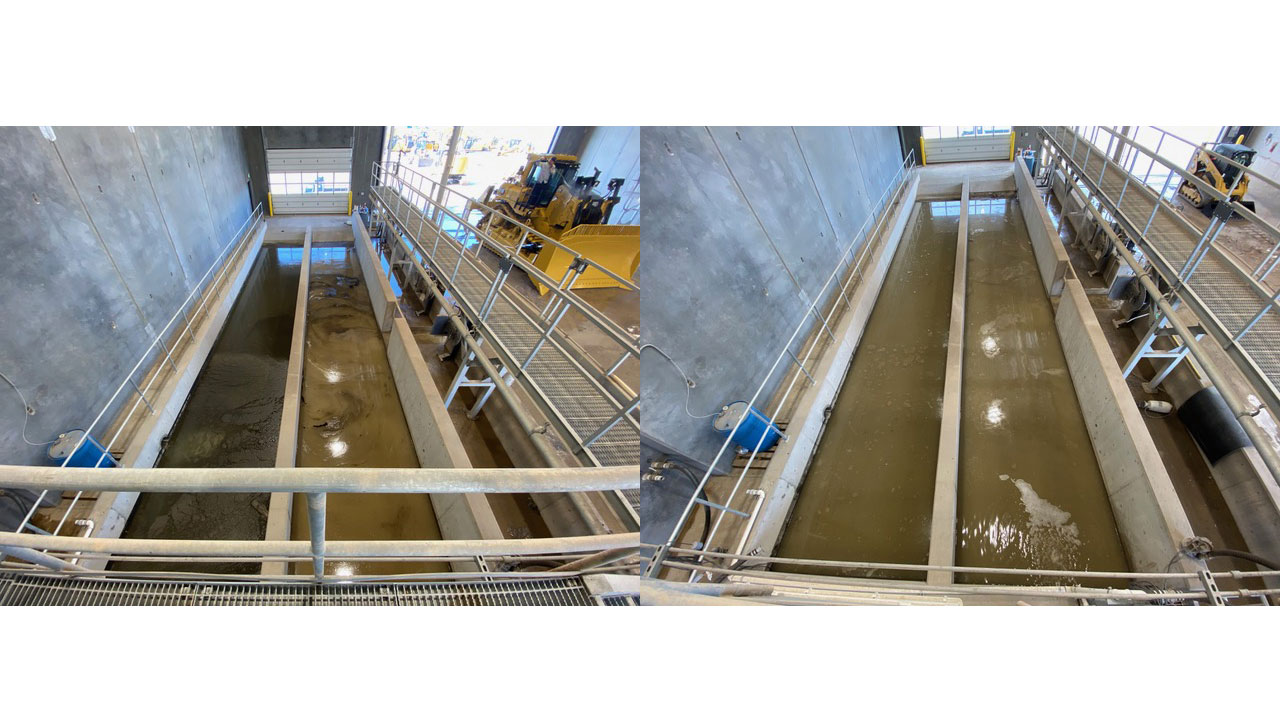

Using Biodigesters with Hydrokleen filtration and Recycling Systems

Liquid Biodigesters should be dosed into the Hydrokleen systems at a rate of 3-ounces per day for each 500 gallons of system wash water capacity. Small regularly recurring doses are preferred over single daily doses. Hydrokleen systems equipped with a logic controller will perform this task automatically, alternately the Automatic Liquid Dosing System may be used.

Hydrokleen systems are designed to maintain optimum conditions for best Biodigester performance: dissolved oxygen levels of at least 3 parts per million, pH between 6.6 to 7.4 and temperature between 70-90℉.

Dry formula Biodigesters are seldom used with Hydrokleen systems. They are activated when mixed with water and have a fairly short shelf life as a concentrate. They work well as a 'shock' treatment for systems that have been idled or systems used without regular Hydro Biodigester dosing long enough to begin to smell. Use of this product as a shock treatment may require pre-treatment with an oxidizer. Contact Hydro Engineering Innovation for more information.

Biodigesters Safety

The responsibility for safety of biological products falls on the shoulders of the United States Food and Drug Administration (USFDA) and the Association of American Feed Control Officials (AAFC)).

Any company that produces biological products may elect to certify their producs to use only those bacterial strains listed on the Generally Regarded as Safe (GRAS) listing authored by the FDA and/or the Association of American Feed Control Officials (AAFCO).

Many companies do not certify to this standard through lack of proof and/or adequate testing measures. Misrepresentation of this certification carries both civil and/or criminal penalties.

These regulatory agencies are the American consumer's only assurance that a bacterial product is safe. All Bio-Future biological products are certified to use only bacterial organisms found on both, the GRAS and AAFCO lists.

To learn more about Hydro Biodigesters, click here.