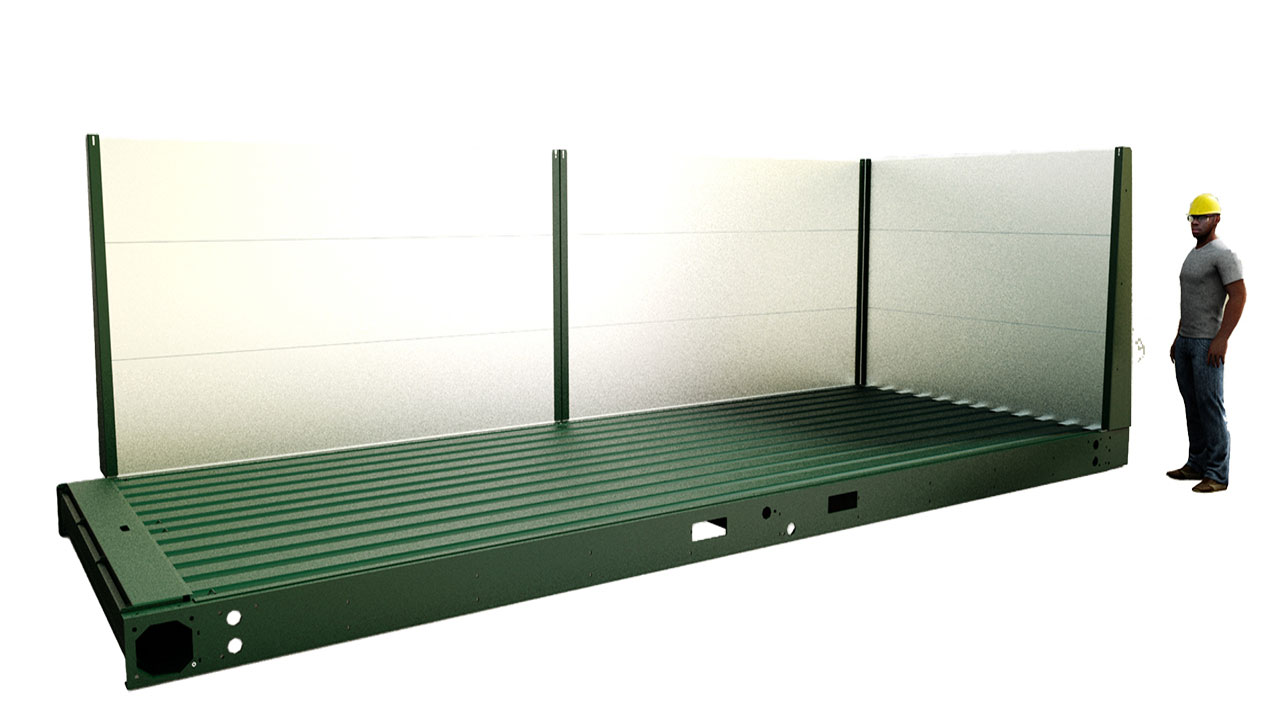

Vapor Blasting Containment Systems

Containment Videos

Vapor Blasting from Hydro Engineering on Vimeo.

Greener Blast from Hydro Engineering on Vimeo.

Non-functioning booths can be converted to a vapor blasting booth for just a fraction of the cost of major repair or replacement. Our Hydroblaster pressure washers, filtrating Hydrokleen units, and Hydropad wash racks can be combined to create a clean, environmental solution for washing your heavy equipment.

FAQs

Do you remove coatings, rust or other contaminants from equipment, tanks, buildings, ships, offshore buoys, etc.?

If so, Vapor Blasting may be worth looking into.

Does your operation currently have a room for sand blasting?

If its in need of replacement or expensive repairs we can help.

Are you concerned about the initial investment for a blasting booth? Air quality regulations, air handling/filtering equipment, blasting PPE, in ground accommodations for a blasting booth, etc.?

A Hydropad blasting system is generally 1/2 the cost

Can you foresee the need to relocate your blasting booth, is your current booth re-locatable?

Everything is above ground with a Hydropad containment system and can be easily relocated.

Do you plan on separate washing facilities to follow your blasting operation?

Both blasting and washing can be performed in the Hydropad containment system

Will your operation benefit from a mobile, environmentally compliant Vapor/Slurry Blasting System to tackle such jobs as removing coatings from large oil tanks or ships?

Our Blasting Booths, Washing Rooms, Hydroblasters, Chemical delivery Systems and Wash water Treatment packages can be used.

Are you in the process of planning a new facility to include a surface prep/media blasting room?

If so, please allow our specialists the opportunity to provide you with a design and quotation.