Water filtration and recycling for Screen Printers

Solids filtration in screen print operations is critical. Emulsion can coat your drains just like they coat your screens. We have a couple of great options for emulsion filtration.

There are more solids filtration systems (CFS3) in screen print shops around the world than any other filtration systems. Why? It's simple and it works. The CFS3 is an all stainless-steel system that filters wash water down to 20 microns nominal. Two reusable stainless steel classifier screens and a disposable bag filter provide filtration for print operations for 10 screens per day.

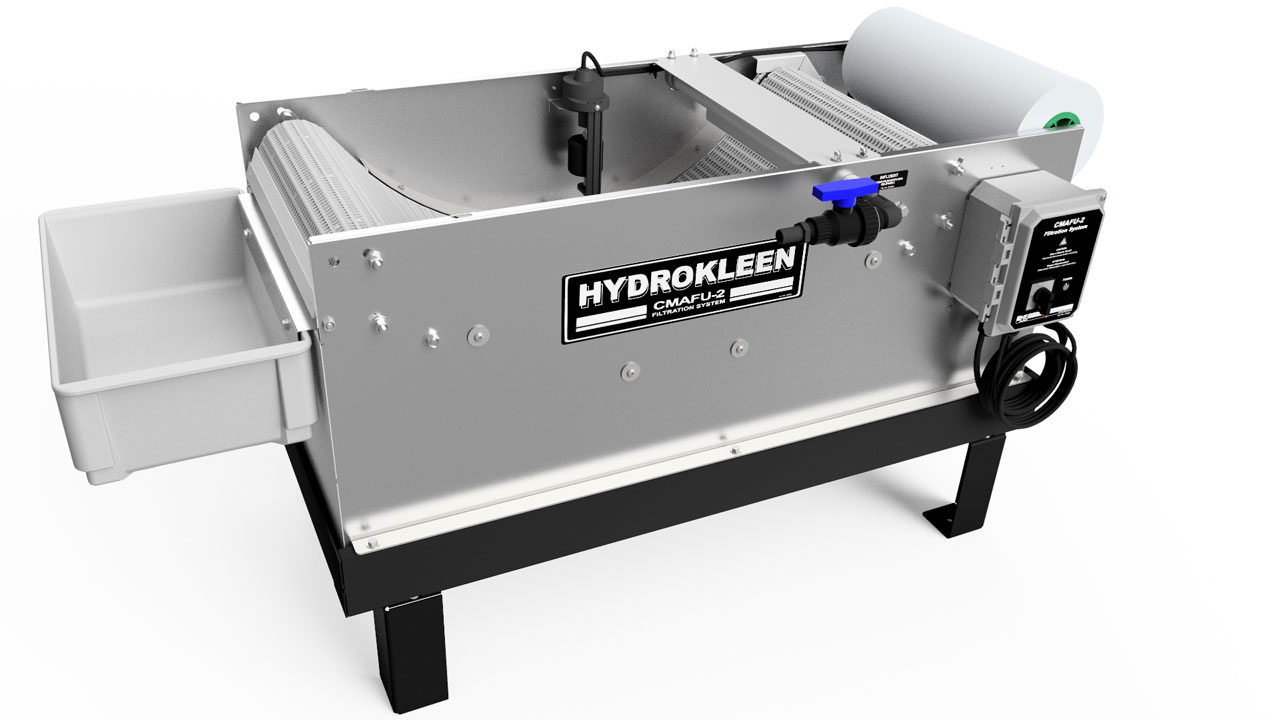

The CMAFU-2 solids filter is automatic and can handle wash water flows to 8 GPM continuously. That is more than enough for 2 handheld pressure washers running simultaneously. No filters to change here; the CMAFU is automatic. As the filter media (paper) becomes plugged it automatically advances. Spent paper drops off into a container for simple disposal. Just run it through your dryer and in the trash it goes, like a misprint. The CMAFU-2 is the first step of filtration for screen printers, reclaiming more than 10 screens per day.

Single and dual polishing filtration systems (models ACF3, SPL30 & DPL30) provide filtration for acceptable discharge to sewer or recycling of wash water . Discharge to sewer or ZERO DISCHARGE...it's your choice.

In order to meet discharge requirements or recycle screen reclaim water, the following will need to be accomplished:

- Source reduction of chemicals used in screen reclaiming is imperative

- Solids removal

- Hydrocarbon elimination

- Bioreactor hydrocarbon & organics elimination