Tactical Military Wash Racks

Hydro Engineering, Inc. tactical equipment wash rack systems are portable, above ground wash racks designed to wash small to large vehicles and equipment, and to collect and recycle wash water. This is equipment and does not require design, construction and in many cases permitting, particularly when no sewer connection is made.

What makes up a Hydro Engineering, Inc. tactical equipment wash system:

- Hydrosite custom built portable equipment building; the Hydrosite is portable equipment built with factory installed pressure washers, wash water filtration and recycling equipment, heating, lighting and ventilation components, support subsystems and controls to perform effective wash/rinse decontamination.

- Hydroblaster pressure washers

- Hydrokleen wash water filtration and recycling equipment

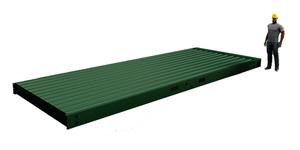

- Hydropad portable equipment wash rack

All equipment installed within the Hydrosite portable equipment building is individually ETL certified to the appropriate UL, CE And CSA safety standards. The Hydrosite, as an entire system, is also ETL certified.

Hydro Engineering, Inc. tactical equipment wash rack systems are on GSA schedule! Individually, all equipment within the tactical military wash rack package are also on GSA schedule.